I found a pretty good enclosure for my 3D printer. Cost of this was a little less than $100.

Main parts:

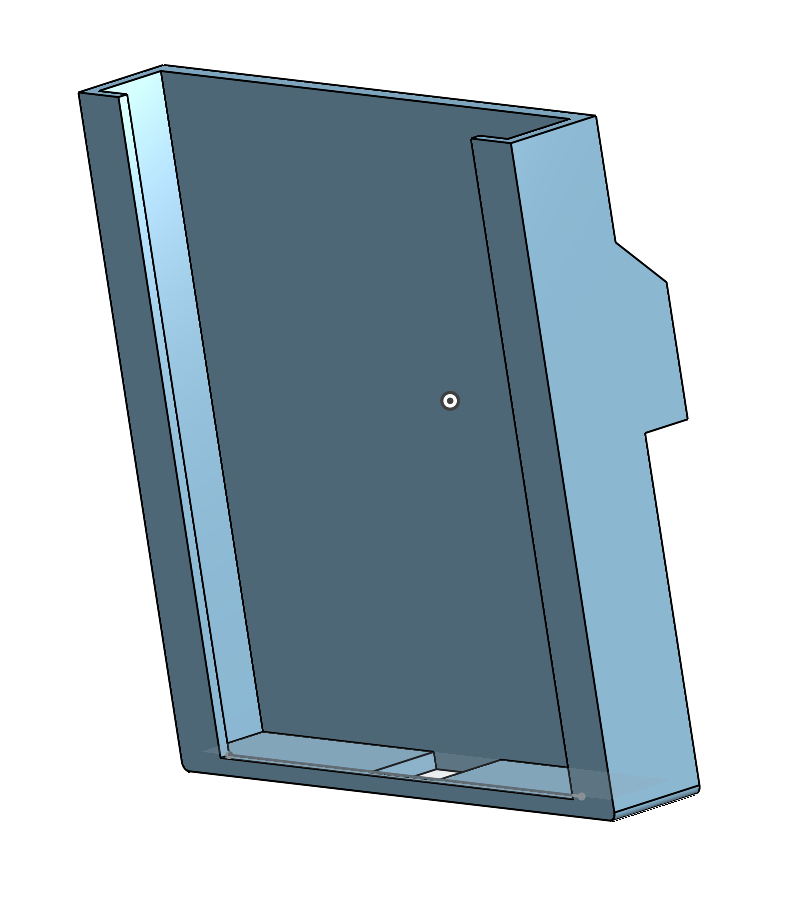

Ikea Sektion Cabinet - It comes with two doors and hinges.

D x W x H = 24in x 30in x 20in

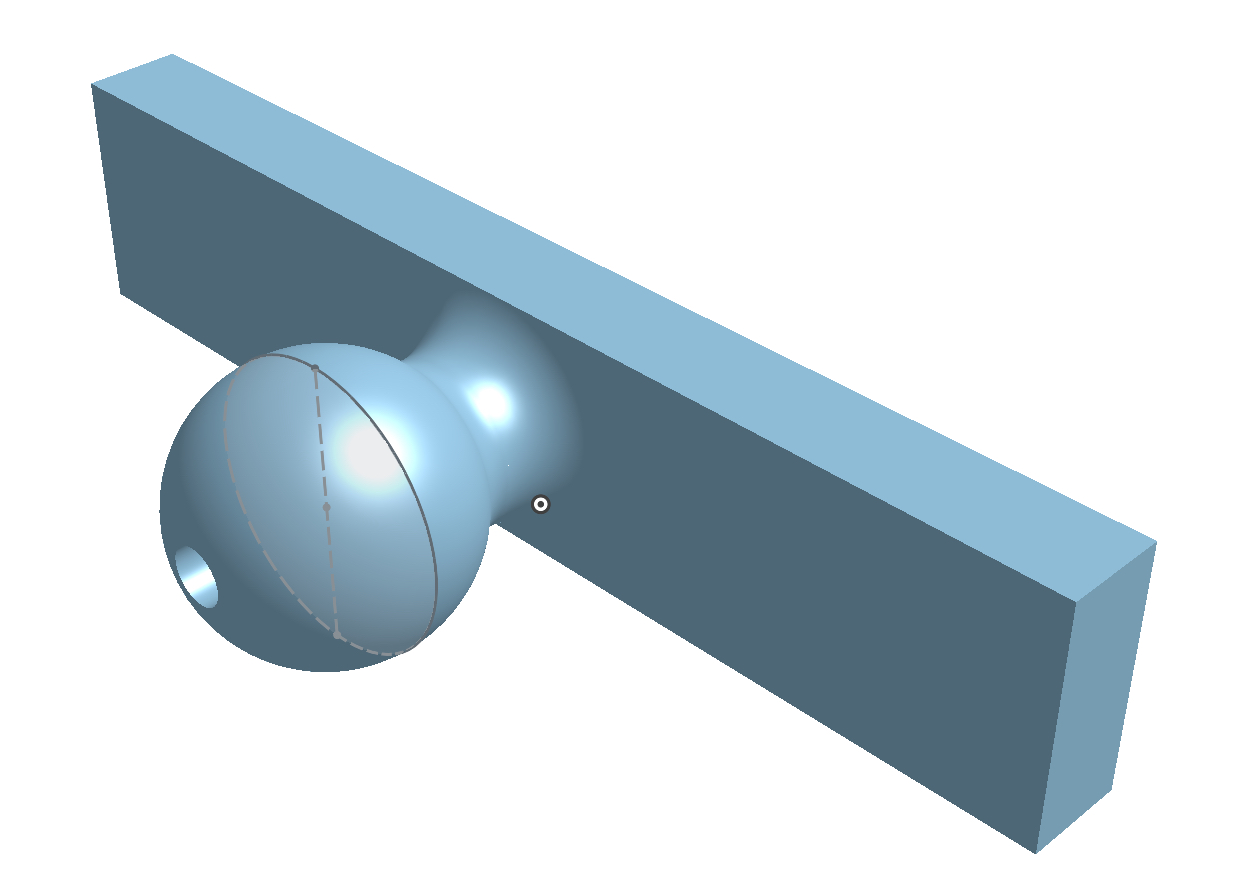

Enclosure Fan - If not printing ABS, this helps keep the enclosure cool enough to print PLA.

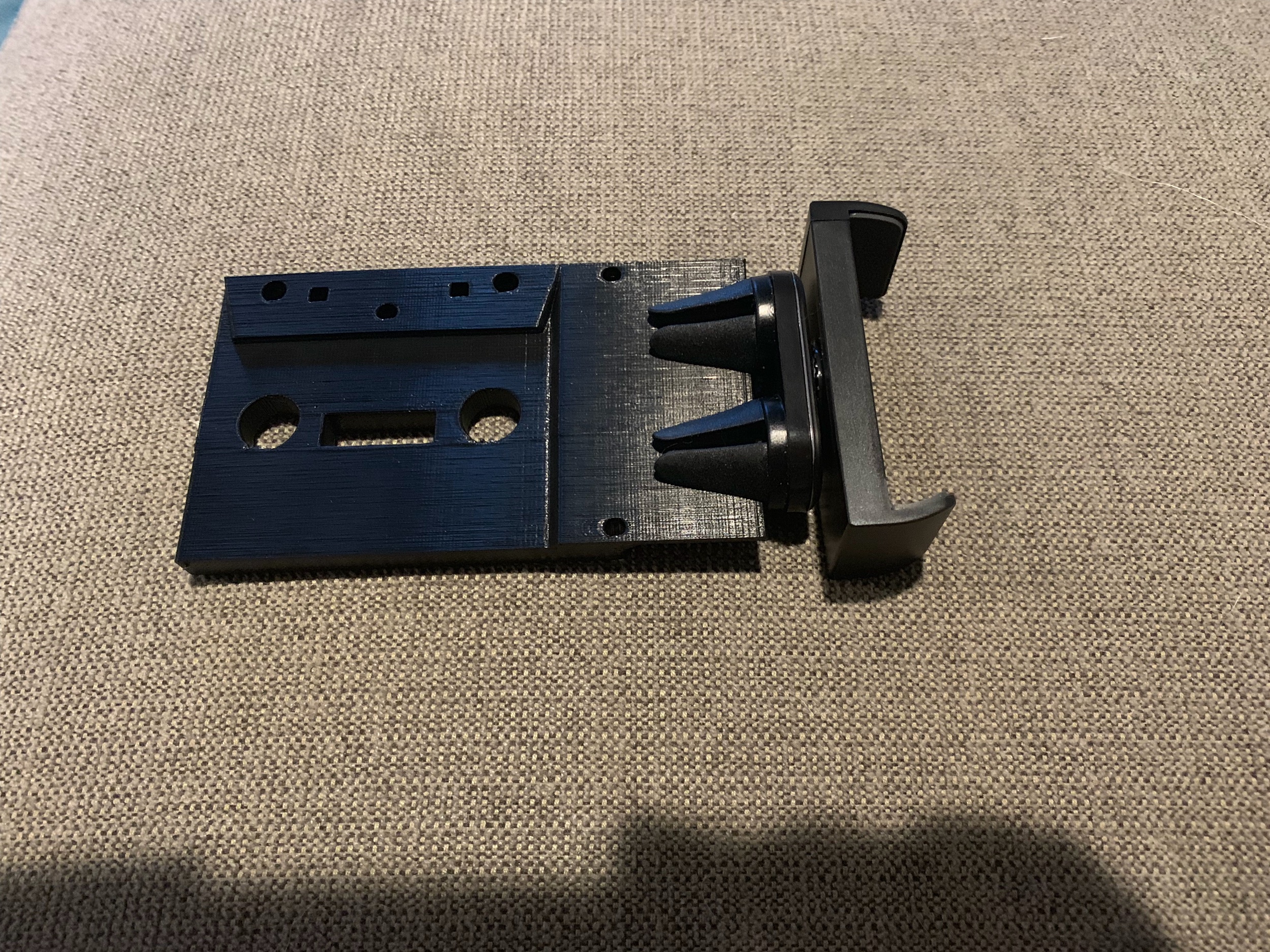

Printed Parts:

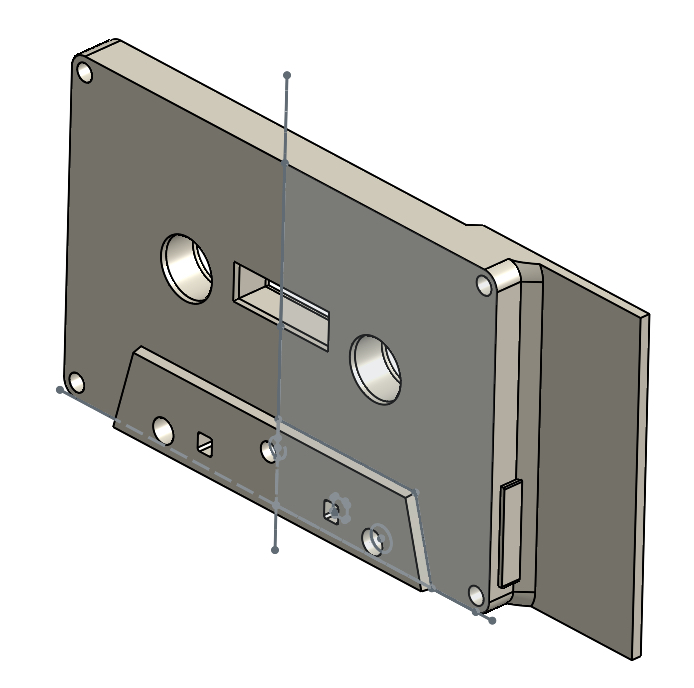

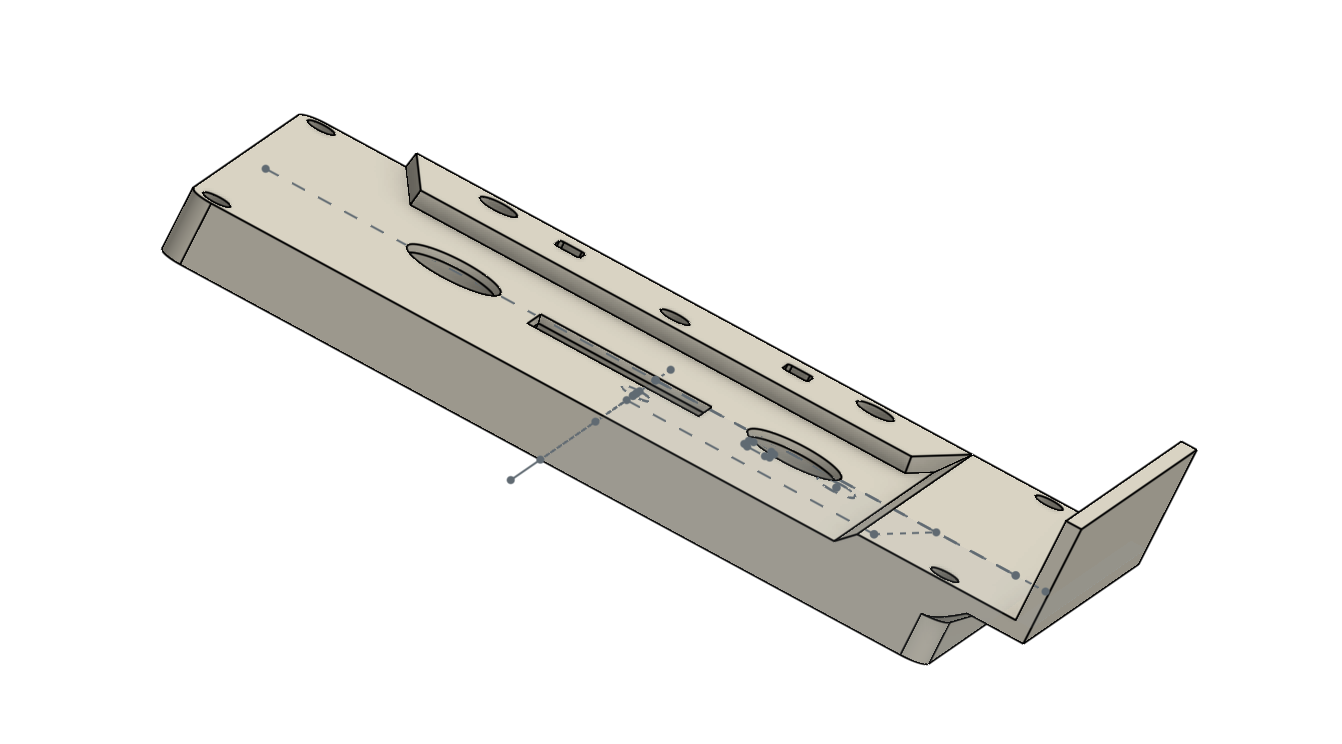

Lack Filament Guide - Cut a hole to allow for the filament to go through the top

The key thing is that this will get you up and running fairly quickly. It’s sturdier than the traditional Ikea Lack tables that everyone seems to be using. There are also holes in the back to allow for cables to come in and out of.

I’m able to maintain temps of 101F/38C, which has helped me print ABS reliably. Another fan is probably needed to achieve adequate ventilation, but i just leave the doors open otherwise. The Fan system has a lot of cool features: fans full on or temperature dependent on. I’ve also added a carbon filter to the fan to filter the fumes from printing ABS.

You can fit this vertically if you do not have any other accessories to the side of the printer. I had my webcam mounted on the x-axis and so ti wouldn’t fit that way.